NCEL Blog

“Chemical Recycling”: Backend Fix or Toxic Technology?

November 16, 2023

“Chemical recycling” (also called advanced recycling, plastics renewal, or molecular recycling) continues to be a much-discussed topic in plastic pollution and policy circles. But just what is “chemical recycling”?

It stands in contrast to the type of recycling most of us are familiar with, which uses mechanical processes such as sorting, washing, shredding, and grinding to recover materials without changing their chemical structure. On the other hand, “chemical recycling” is an umbrella term for a variety of processes, including pyrolysis, gasification, and depolymerization–all classified as incineration–as well as solvolysis, methanolysis, and glycolysis. All of these “chemical recycling” processes break down the chemical structure of post-consumer plastic with some combination of heat, pressure, catalysts, and/or solvents to turn it into either fuel or new plastic products.

The State of “Chemical Recycling”

Though “chemical recycling” is much discussed, there are currently only 11 constructed plants in the U.S. and their output remains low as they continue to fail to meet internal goals, as detailed in a new report. Some of these plants have been operating in pilot or test modes for years or even a decade and have failed to scale up. Even if all 11 of these facilities were to operate at full capacity, they would process less than 1.3% of plastic waste generated yearly in the U.S. When compared with the still low 5-6% of plastic that is recycled overall, “chemical recycling” remains just a drop in the bucket.

The Impacts of “Chemical Recycling”

The varieties of “chemical recycling” technologies come with a number of questions, challenges, and risks in terms of climate impacts, health, and environmental justice. Within “chemical recycling” there are two broad types of processes:

- those that convert plastic to fuel (pyrolysis and gasification), and

- those that convert plastic to plastic.

Based on an NRDC investigation, the vast majority of “chemical recycling” is plastic-to-fuel. This process takes a fossil fuel-based product, breaks it down in an energy-intensive process, and produces a fossil fuel that will be burned again.

Climate Impacts

Plastic-to-fuel processing emits three tons of CO2 for every one ton of plastic. A DOE study found that the “environmental metrics of pyrolysis and gasification are currently 10-100 times higher than virgin polymers due to low yields . . . and high energy requirements.” Not only is the climate impact of plastic-to-fuel significant, it also incentivizes plastic production. Further, plastic-to-fuel perpetuates more plastic waste, and does not accomplish the aim of recycling, which should produce a new, reusable product.

Health

While the output of the 11 U.S. “chemical recycling” plants is low, the output of hazardous waste is high, according to studies from the NRDC and Beyond Plastics/IPEN. “Chemical recycling” releases toxins into the environment as air emissions, byproducts, and residues, and that is on top of the toxins already inherent in plastic. Health effects from these toxins can range from respiratory and neurological to cancer or genetic mutations. In addition, the new fuels generated from plastic waste are not regulated under the Clean Air Act.

Environmental Injustices

Similar to plastics manufacturing, NRDC found that “chemical recycling” facilities are largely sited in low-income and/or communities of color, exacerbating environmental injustice and compounding cumulative impacts. Based on a new analysis of the 11 “chemical recycling” plants, eight are located in lower-than-average income areas and seven are located in communities with a higher-than-average concentration of people of color. Additionally, there is a trend for companies to co-locate “chemical recycling” facilities alongside other petrochemical facilities, intensifying environmental injustice and cumulative impacts.

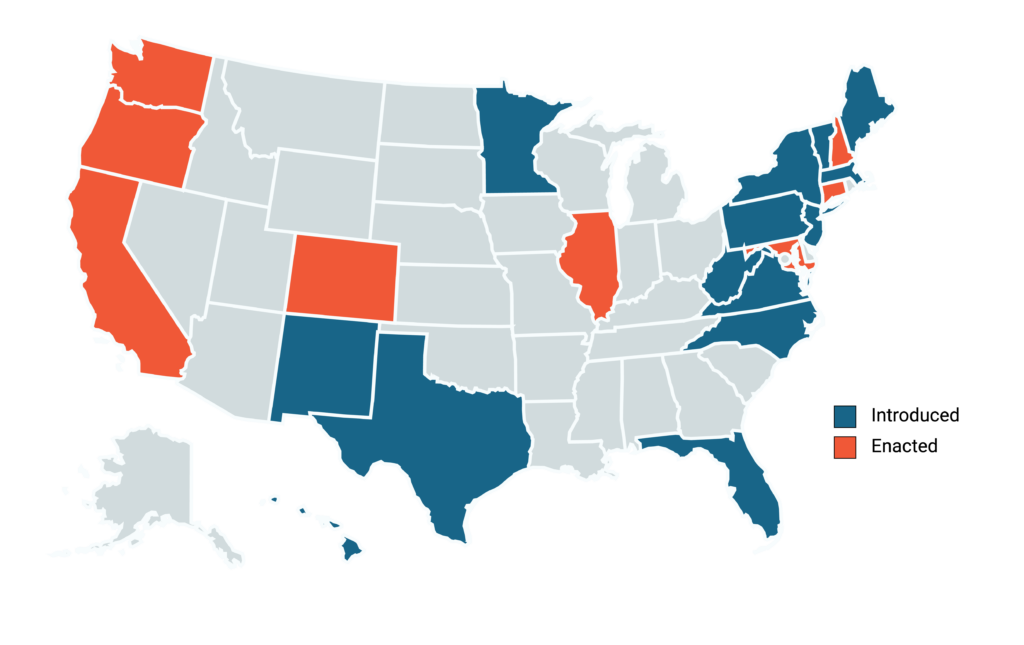

State Action on “Chemical Recycling”

States have proactive policy options such as bans or moratoriums and defining recycling to not include “chemical recycling” technologies. For example, Rhode Island H.B.5142 would prohibit any type of new high-heat waste processing facilities in the state. Defensive policy options include enacting guardrails around existing laws and requiring public notice, participation, and reporting. New Hampshire S.B.267 would require a “cumulative impacts analysis” for all of the Department of Environmental Services’ rules and statutes moving forward.

Zooming back out from “chemical recycling” to the entire plastics life cycle, NCEL’s Zero Waste Policy Roadmap for a Plastic-Free Future (created in collaboration with partners GAIA, Safer States, and Upstream) provides a comprehensive overview of points of intervention and policy options at every stage of the plastics life cycle.

One of the Roadmap’s key takeaways is that to effectively address the plastic pollution crisis, source reduction and reuse need to be prioritized over recycling. For example, 15 states considered single-use plastic bans and fees in 2023. More broadly, 22 states have proposed legislation around plastic pollution in 2023.

To learn more about policy solutions for the plastic crisis, check out the Zero Waste Policy Roadmap.